Erosion Control Mats – Steep Slope and Channel Installation

Erosion control mats are an economical and efficient way of controlling soil erosion in a variety of applications. There are different installation methods for use on slopes and channels that must be carried out correctly to be effective. Even the type of anchors used to secure the mats provide different benefits based on the site’s conditions. Having a firm grasp of each installation method is essential to a successful project.

Stakes

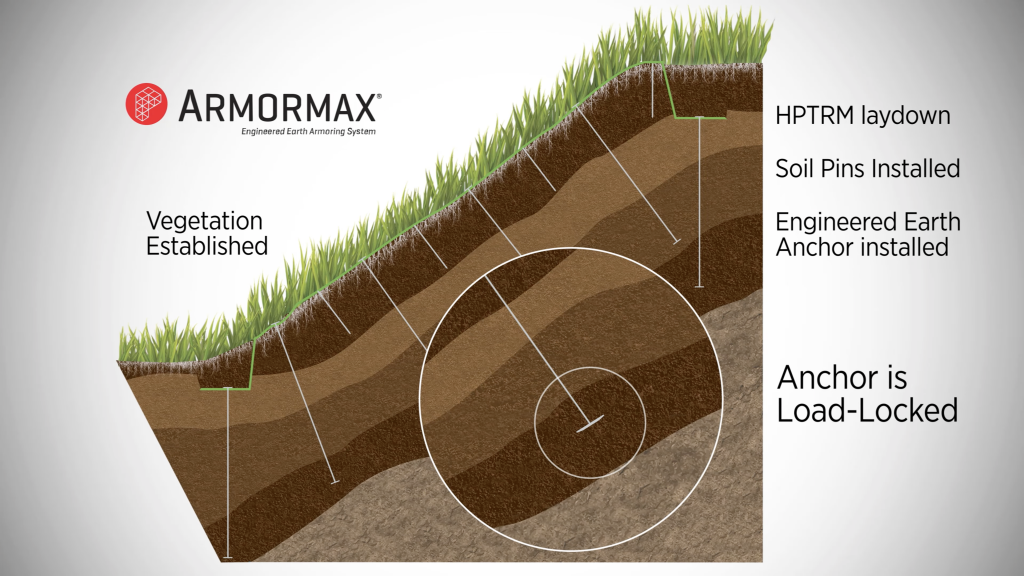

If you’re installing erosion control mats, you need to know how to secure the mats to the soil. Projects that require long-term, strong erosion control and a more powerful anchoring system are better suited by using Engineered Earth Anchors™ (EEA). EEA is manufactured from a corrosion-resistant material that is connected to a zinc-aluminum coated carbon steel or stainless steel tendon. As the pressure applied to the soil by the ARMORMAX system increases, a body of soil above the anchor is compressed, providing resistance to anchor movement and permanently securing the mat in place.

Installation For Slopes

Installing erosion control mats on slopes requires extensive site preparation. The soil should be graded to be smooth and rid of weeds, debris, rivulets, gullies, caking, and crusting. All voids in the grade should be filled and compacted. Next is seeding. Erosion control mats have the ability to promote vegetative growth, which is a major source of their strength. By using seeds that match the soil conditions of the job site, you can develop the strongest vegetative density & root systems while securing long-term efficacy.

After seeding, it’s time to prepare the anchor trench. Dig a 6×6 inch trench for anchoring the erosion control mats. There should be a minimum of 3 feet from the slope’s crest to the anchor tench, although this may not be possible on all worksites. Installing the mats on the flat above the crest of the grade prevents water from finding its way under the erosion control mats, rendering them less effective. Start securing the mats 30 inches past the anchor trench before rolling the mats down. Drive the stakes into the anchor trench, flush with the soil grade. Once finished, backfill the anchor trench and tamp down the soil. Seed the newly compacted soil and cover it with the remaining terminal end of the mats. Stake everything down the slope of the anchor trench with 12-inch centers.

Now it’s time to deploy the mats. Start at the slope’s crest and roll them down carefully. Every 20 feet, make sure to pull the mat a bit to get rid of any slack. However, you should never stretch the mats because that may cause bridging. Whether or not you overlap the edges depends on the manufacturer’s instructions.

Finally, stake down the mats. Typically, the stakes should be set every 3-5 feet down the vertical axis of the mats. They should also be staggered every 18-24 inches across the horizontal axis. There should be at least 1 or 2 stakes per square yard but harsher terrains may require more. At the toe of the slope, another anchor trench should be made and the mats secured like the top of the slope.

Installation For Channels

The creation of man-made channels is greatly benefitted by the use of erosion control mats. To prepare a channel site, begin by grading the surface to become smooth and free of stones, weeds, sticks, roots, debris, rivulets, gullies, caking, and crusting. Any voids in the grade must be filled and compacted. During seeding, use seeds that match the soil conditions of the job site. You may need to use different seeds above and below the waterline, depending on the expected water conditions when the channel is filled.

Erosion control mats should be first unrolled on the channel floor in the same direction that the water flows through the channel. Make sure there is a minimal amount of seams at the bottom of the channel and no seams in areas where there will be a strong water flow. Adjoining erosion mats should be installed away from the center of the channel bottom. Abut the mats according to the manufacturer’s guidelines, will let you know whether or not to overlap sections. If the guidelines call for overlapping, overlap the mats by 2-4 inches. Install a row of stakes along the offset center overlaps at least every 2 feet.

To secure the mats at the start of the channel, the Federal Highway Administration recommends digging a 6×6 inch check slot. The slot should be perpendicular to the water flow across the channel’s width. Lay the erosion control mat down in the check slot and extend 30 inches of the mat past the check slot. Stake the mats into the check slot on 12-inch centers. Backfill the anchor trench, compact the soil and place seed over the area. Put the 12 inches of the mat’s terminal end over the soil and stake the terminal end down-slope of the anchor trench. Again, stake down on 12-inch centers.

The Federal Highway Administration also recommends checking slots to be dug perpendicular to the water flow. Do this down the width of the channel every 25 feet and at the terminal end of the channel. Roll out erosion control mats down the bottom of the channel and slope in the direction water will flow. Up-slope erosion mats should overlap the downslope mats by 2-4 inches. Anchor them down with a stake pattern of one per 25 inches for the width and 36 inches for the length. Finally, the mats should be stakes at the terminal end of the channel with the same type of check slot as the start of the channel.

High-Quality Erosion Control Mats

No matter the application, you will need high-quality products to get the job done. Founded with the purpose of developing products to protect our environment, IWT Cargo Guard’s mission is to provide the most efficient and cost-effective products for your project. By quickly analyzing the products and services required for the project, we become an extension of your estimating department. Our commitment to both our clients and the environment is the cornerstone of our business. Our core values of honesty and integrity along with exceptional service are at the heart of everything we do. You can be confident that you can rely on our support throughout the duration of your project and beyond. At IWT Cargo Guard, we have the knowledge and experience to help you choose exactly what you need. Contact us today.