The Curtain Ballast: Why Your Turbidity Barrier Needs One

If you work in the environmental and civil engineering industries, chances are you have worked with a turbidity barrier before. These floating silt curtains are designed to control sediment within a body of water and are constructed using a combination of impermeable geomembranes and permeable geotextiles. Whether you are completing construction work downslope or in a sensitive wetland location, turbidity barriers are extremely helpful tools. They typically consist of floats, curtain, ballast, and anchor lines. In this blog, we will be focusing on the curtain ballast.

What is a Curtain Ballast?

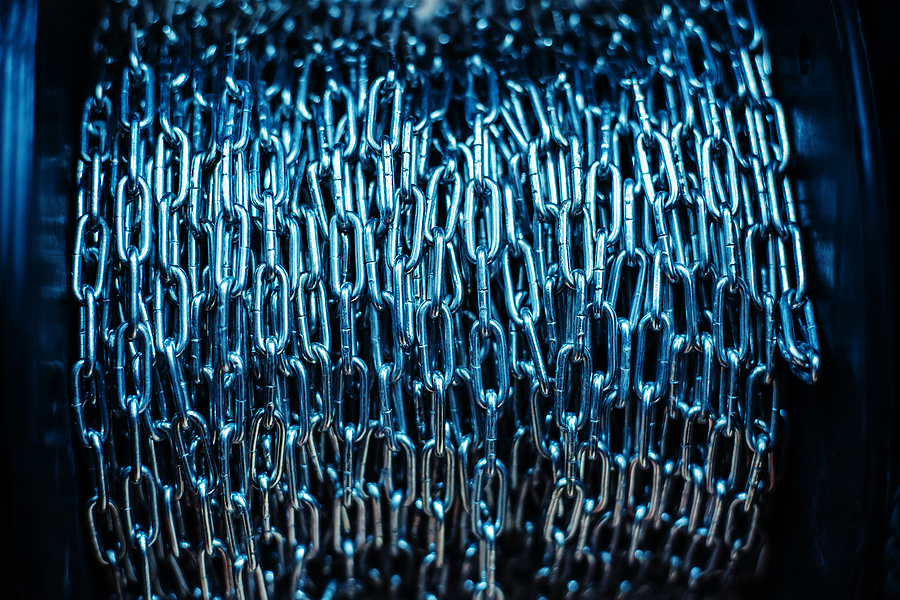

A curtain ballast can be found at the bottom of the turbidity barrier. It is a heavy galvanized steel chain that is sealed into the hem along the curtain, enclosed in a PVC pocket. PVC binding and heavy webbing are typically used to reinforce the grommets. Depending on a specific project’s requirements, the size and weight of the ballast chain can vary. In extreme cases, multiple ballast chains can be used.

This chain provides “ballast,” a word meaning stability as a result of added weight, to keep the turbidity curtain vertical in the water. If there is unavoidable silt and sediment movement in the water surrounding construction, a curtain ballast will help the turbidity barrier remain upright and functional.

In currents, swells, and tides, the curtain will billow beneath the water. The ballast chain helps to provide the necessary counter-weight to decrease the billowing angle.

Do Ballast Chains Keep Curtains at 90 Degrees?

So far we have used the terms “vertical” and “upright.” However, it’s important to understand that curtain ballasts do not keep barriers completely vertical at 90 degrees in the water. Hydrodynamic forces beneath the water make holding a completely upright position impossible.

Ballast chains help reduce the chance that the curtain will billow completely and float to the surface. They do not act as anchors and are not intended to be used as connection points for other tension components including anchor lines. Instead, auxiliary anchoring is required in order to keep the turbidity barrier stationary in the water.

How Much Do Curtain Ballasts Weigh?

The amount of weight necessary to successfully hold the turbidity curtain upright in the water depends on the type of curtain you are working with and the waterway. For example, many Type 1 and 2 barriers include curtain ballast chains that weigh 65 pounds. However, this depends on the length of the curtain. On the other hand, Type 3 barriers feature curtain ballast chains that weigh around 100 pounds. In all cases, the weight of the chains depends on the length of the curtain and the specific waterway.

Generally, curtain ballast chains weigh between .65 lbs/ft (for a 1/4” chain) and 1 lbs/ft (for a 5/16” chain). The examples above indicate turbidity curtains that are between 65 and 100 feet in length. They are usually made in lengths of 25, 50, or 100 (which are joined together to make one continuous containment barrier). In these cases, more than one curtain ballast may be used along with heavier chains.

Professionally Constructed Turbidity Barriers

For turbidity curtains that are effective, functional, and remain floating vertically in the water, look no further than IWT Cargo-Guard.

Our experienced professionals are at the forefront of the evolution of turbidity barriers and curtain ballasts. From skirt reefing lines to deep depth skirts or bed load baffle systems – you name it, we have the product and solution you need. Whether you’re completing dredging projects, pile driving, or shoreline restoration, IWT Cargo-Guard offers durable equipment that can withstand the harshest of job site conditions.

Contact our team today to keep your turbidity barriers upright, your budgets satisfied, and most importantly, the environment protected.